Common Gold Mining Machinery Used in the Gold Mining Process

At present, the cyaniding process is one of the most widely used gold mining processes for the gold extraction, which can also be divided into many kinds of gold mining process, each of them needs different gold mining machinery. Here are some common gold mining machinery used in the gold mining process.

Generally, the conventional cyanide leaching process includes three steps: leaching process, washing process, and zinc powder replacement process. In the CIP and CIL process, the activated carbon is used to extract gold, so the last step of these two processes becomes activated carbon adsorption process.

The main gold mining machinery used in the cyanide leaching process includes the leaching agitation tank, high-efficiency low-consumption rapid desorption electrolysis system, washing thickener, zinc powder replacing device.

Among them, the leaching agitation tank is applied to the conventional cyanide leaching process, the CIP process and the CIL process. The desorption and electrolysis system is mainly applied in the stage of activated carbon adsorption. The zinc powder replacement device is the main gold mining machinery used in the zinc powder replacement stage. The washing thickener is the primary gold mining machinery used in the washing stage of the conventional cyanide leaching process.

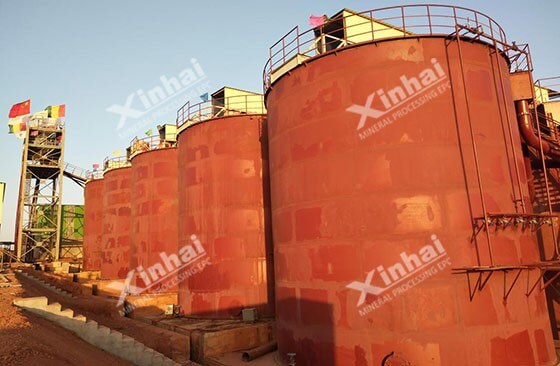

1. Leaching agitation tank

The leaching agitation tank is mechanical agitation equipment used in cyanide leaching operation of gold mine. There are two kinds of leaching agitation tank: single impeller leaching agitation tank and double impeller leaching agitation tank. The working principle of leaching agitation tank is: the slurry flows from the top to the bottom in the center under the action of impeller pushing and throwing. Then, it is diffused through the peripheral baffles, and air is supplied to the lower end of the shaft (the air is fed by the hollow shaft) and the slurry is circulated upward to form a uniform suspension mixture.

Now the mines and refineries need continuously leaching, so the slurry concentration deeply affects the leaching rate of gold. If the slurry concentration was too low, the leaching time of pulp would be reduced; if the slurry concentration was too high, the requirements on the pump would be stricter (Generally, the conveying concentration of slurry pump should not exceed 30%. Once it exceeds 30%, the conveying quantity would be affected). In short, double impeller leaching agitation tank has the following advantages, reliable, easy to operate,convenient to maintain, and highly applicable, except requiring high concentration and fineness of the slurry, which made it widely used in the gold processing industry.

The desorption electrolysis system is used as the gold mining machinery for extracting gold adsorbed in activated carbon,which usually works under high temperature and high-pressure conditions,including carbon lifting pump, carbon screen, desorption solution tank, desorption column and others.

The working temperature of desorption electrolysis system is as high as 150°C, which is about 55°C higher than the working temperature of the heating and atmospheric pressure process; the pressure is up to 0.5 Mpa, which is 0.2 Mpa to 0.5 Mpa higher than the normal temperature and pressure process. Under this high temperature and pressure condition, the desorption electrolysis rate of gold-loaded carbon is obviously accelerated—-only 2 to 6 hours to absorb 98% of the gold, which greatly improves the absorption efficiency, shortens the desorption time by nearly ten times, and reduces the lean carbon grade to 50g/t. It also has a regenerative activation effect on activated carbon.

Compared with the heating atmospheric pressure process, the desorption electrolysis system only needs sodium hydroxide as the desorption solution, and does not need sodium cyanide, whichnot only reduces the operating cost, but also meets the requirements of environmental protection. In addition, the whole desorption process is basically carried out under the same temperature and pressure, desorption solution can be directly into the electrolytic cell without cooling treatment, which greatly saves the consumption of heat energy, and the consumption of electricity is only 1/2-1/4 of the heating atmospheric pressure process, truly realizing cyanogen free low-consumption desorption.

During the operation of the system, the amount of liquid in the system will fluctuate to some extent due to the liquid vaporization and pressure change of the system. Therefore, technicians specially set up a liquid level buffer mechanism to automatically offset liquid level changes and maintain the normal operation of the system. In addition, for it is configured with a temperature control system, when the temperature reached set value, the system will automatically pick the open part of the electric heater, residual electric heater automatically maintain system working temperature, when the system temperature is lower than the set limit, was torn open electric heater automatically into start, ensuring that the system has been stable in temperature range.

Zinc powder displacement process includes three stages: purification of pregnant solution, deoxidation and displace mentfiltration. The suspended substance in the gold-bearing pregnant solution is removed by purification stage. The dissolved oxygen in the pregnant solution has an obstructive effect on the gold recovery by zinc displacement, so the oxygen in the pregnant solution must be removed to ensure the smooth progress of gold recovery. The displacement filtration stage includes zinc powder addition and displacement operation. The displacement reaction starts once the zinc powder is added into the pregnant solution. And the final displacement and filtration of gold mud are completed by the displacement device.

Therefore, zinc powder displacement device,a common gold mining machinery, mainly includes deoxygenation tower, zinc powder feeder and displacement device.

4. Washing Thickener

Washing thickener is the professional gold mining machinery for the solid-liquid separation and washing of pulp after cyanidation, which has two types of two-layer and three-layer. It has advantages such as small occupied area, energy-saving and simplification of process flow. Successive discharging was applied for reducing several circling of liquid gold and early to recovery. At same the period during pulp in thickener was reduced and leaching rate was increased. As an important gold mining machinery, the washing thickener realizes reverse washing, continuous operation, large volume and high washing efficiency. Small area, reasonable structure, low operation and maintenance cost.

The working principle of washing thickener is that: Pulp by feeding tube into the, free settling in the pulp of rake area by the pressure of scraper step into a concentrated, gradually by rake to pool center, by the row ore mouth by gravity into the next layer in the pool, water is entered into the most lower level for material washing distribution box, the bottom of spillway flow distribution box to enter the upper material for washing, the overflow of the first floor of the overflow weir discharge, after washing the bottom material is twice.

评论

发表评论