What Factors Should be Considered in Choosing Grinding Milling Machine?

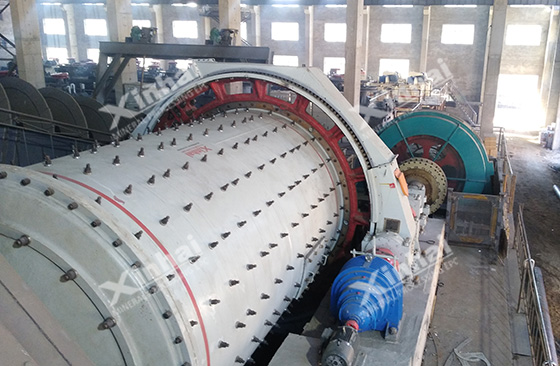

Grinding milling machine is the key equipment for crushing materials after the crushing process. The mineral can be dissociated from the monomer through grinding, and the grinding fineness is one of the main factors affecting the ore dressing index. In the whole mineral process, the cost of grinding milling machine accounts for a considerable proportion. In addition to the price, what factors should be considered when choosing grinding milling machine? How to choose the grinding milling machine at good values?

1. Ore characteristics

It is necessary to make a detailed study on the grindability of ore in the mineral processing test. The hardness of ores is different due to their different properties. Those ores that are easy to crush, such as fluorite, tin, etc., are different from other ores. So, the overgrinding problem must be considered when selecting the grinding milling machine. For example, the rod mill has a certain selective grinding effect, who has even product particles and less overgrinding. Because the gravel mill does not use metal medium, so the influence of iron impurities on rare metal dressing process is reduced. When the autogenous mill is used, the feasibility of ore self-grinding should be proved by the medium performance test.

2. Product particle size

Product particle size is also one of the factors influencing the choice of ball mill. For example, the upper limit of product particle size of grid type ball mill is 0.2~0.3mm, which is mostly used for the first grinding stage. The product particle size of overflow type ball mill is generally less than 0.2mm, which is suitable for fine grinding operations.

3. Efficiency of grinding milling machine

When choosing the grinding milling machine, we consider not only the price of grinding milling machine, but also the efficiency of grinding milling machine. If the selected grinding equipment has low efficiency, it will inevitably increase the time cost and economic cost of the whole concentrator. If the grinding equipment uses good ball mill liner, which can save the energy, reduce the noise, and improve the grinding efficiency. In addition, the energy consumption of grinding milling machine accounts for 65%~75% of the total energy consumption of the whole concentrator. Energy saving, low consumption and high efficiency are always the top priority of g grinding milling machine operation in the concentrator. Therefore, it is important to select the grinding milling machine with high grinding efficiency, which also require a higher level upon the grinding mill manufacturers.

4. Grinding mill manufacturers

Nowadays, the grinding milling machine market is mixed. It is suggested that all mine owners should inspect the scale, strength and customer feedback of the grinding mill manufacturers, so as to ensure the normality of the grinding mill manufacturers. If the conditions permit, the mine owner can visit the production site of the grinding mill manufacturers. At the same time, it is also necessary to consider the on-site installation service and after-sales service of the grinding mill manufacturers, whether the manufacturer arranges professional technicians to guide the installation and debugging, and whether the manufacturer provides corresponding technical training.

In addition to the above factors, other factors should also be considered when choosing grinding milling machine. In general, grinding equipment is an operation with high energy consumption, which directly affects the cost of the whole concentrator and the subsequent separating index. Only by choosing appropriate grinding milling machine can the economy and efficiency be maximized.

评论

发表评论